Departments

Our institute is divided in 4 departments, which represent the main fields of corrosion protection. The insitute has also many high-class systems and equipments for corrosive strain and analysis of samples, which are conform to the latest state of the art in their working fields.

Auch das akkreditierte analytische Labor des IKS ist für alle Problemstellungen des Korrosionsschutzes hervorragend ausgerüstet. Modernste Analysentechnik dient den Kunden und allen Abteilungen des IKS als Grundlage bei der Aufklärung von Schadensfällen, zur Prozessüberwachung und zur Forschung.

Viele der Belastungs-, Prüf- und Analysegeräte sind DakkS-akkreditierte Prüfmittel.

Nachfolgend finden sie detailierte Informationen zu unseren 4 Fachabteilungen, sowie deren wichtigsten Anlagen und Geräte.

The department “Metallic Materials and Electrochemistry” investigates the corrosion behaviour of metallic materials and coatings in relation to the variety of ambient conditions depending on their structure and surface condition or in contact with other materials. The objective is the suitable usage of materials in regard to corrosion protection.

The corrosion behaviour is assessed by means of electrochemical standardized methods, such as potential and current measurements, as well as noise and impedance measurements.

The laboratory is equipped with modern technology, e.g. potentiostats with ZRA-mode and different measuring cells which are customised in regard to the respective measurement purpose.

The actual material or component behaviour is simulated as realistically as possible in model systems, for instance the testing of pipe materials using a Looptest system, which can be operated with artificial seawater or other aqueous media.

Furthermore, the corrosion protection inside and by packing materials during transport or storage is investigated by simulating the exposure to corrosion in climatic chambers.

The department also features a metallographic laboratory for the preparation of high-quality cross-sections and various microscopes for their assessment.

Research and working priorities:

- Corrosion and corrosion protection of metals, also in contact with other non-metallic materials

- Materials for offshore applications

- Corrosion and corrosion protection in cooling systems

- Cathodic corrosion protection

- Temporary corrosion protection

- Corrosion on solder joints and welding seams

- Testing of corrosion protective packing (esp. VCI)

- Corrosion tests in accordance with standardised methods and other regulations

- Development and modification of corrosion test methods, measuring cells and measurement setups

- Corrosion examinations in model and laboratory systems, also using electrochemical instruments

- Electrochemical instrumentation of mechanical and medial material testing

- Investigation of corrosion mechanisms

Head of Department:

Dr.-Ing. Susanne Friedrich

Tel.: 0351 / 871-7108

Mobil: 0172 192 2324

Fax: 0351 / 871 7150

E-Mail: susanne.friedrich@iks-dresden.de

Geräteausstattung

Elektrochemie

Potentiostat / Galvanostat

Messplatz für Elektrochemische Impedanzspektroskopie

Messplatz für elektrochemisches Rauschen

Korrosionsuntersuchungen unter erhöhtem Druck

Laborautoklav

Metallographie

Metallographieausrüstung Fa. Struers

Optisches Auflichtmikroskop

Stereomikroskop

Kalottenschleifgerät

Ionenstrahlätzanlage

Klimakammern

begehbare Klimakammern

Klimaprüfschrank VC 4034

Klimaprüfschrank VC 7034

Klimaprüfschrank VC34034

Klimaprüfschrank VC³7034

Programmierbarer Wärmeschrank

Wasseranlagen

Looptestanlage für Prüfungen von Rohrwerkstoffen in künstlichen Meerwasser und 1m³ Tank

Versuchsanlagen zur Untersuchung der Schwermetallmigration und Korrosion von Werkstoffen und Bauteilen für die Trinkwasserinstallation

Werkstoffprüfung

Hochfrequenzpulser

Mikro-Härtegerät

Auflichtscanner

Zug-Druck-Universalprüfmaschine

Metallographieausrüstung Fa. Struers

The “Organic coatings” department, based on long-time experience, tests and examines the corrosion protection effect of coating systems on different metal substrates.

Particular focus is the testing of coating materials in accordance with the “Technische Liefer- und Prüfvorschriften der Bundesanstalt für Straßenwesen” as well as the testing of coating materials in accordance with the test specifications of the “Deutsche Bahn AG”.

In joint research projects with industry partners, tests in regard to practice-oriented problems of corrosion protection by coatings and development of products and procedures are performed. The technical orientation of IKS Dresden GmbH allows for a complete consideration of corrosion protection systems consisting of metal substrate and coating including issues of preparation and pre-treatment of the metal surface. Points of focus are mechanisms of corrosion protection, adhesion of coating systems, duplex systems, filiform corrosion, et al.

For accomplishing the work in the field of coatings a technical centre for mechanical preparation of surfaces is available, as well as a laboratory for the application of coating material and modern testing technology.

Research and working focus:

- Testing of coating materials and coatings in accordance with standards of corrosion protection

- Suitability testing of coatings during cathodic protection

- Coatings for offshore applications

- Coatings for stainless steels

- Solvent retention in corrosion protection coatings

- Duplex systems

- Powder coatings

- Pre-treatment and application of coated light metals

- Filiform corrosion

Head of Department:

Dipl.-Chemikerin Dr. Andrea Rudolf

Tel.: 0351 / 871-7104

Mobil: 0172 192 2321

Fax: 0351 / 871-7150

E-Mail: andrea.rudolf@iks-dresden.de

Geräteausstattung

Applikation von Beschichtungsstoffen

Flüssig-Beschichtungsstoffe

Pulver-Beschichtungsstoffe

Prüfung von Beschichtungen / Beschichtungssystemen

auf Stahl und NE-Metallen

Salzsprühnebel

VDA

Kondenswasser

Kondenswasser 2

Delta-T

QUV

Xenontest

Wetterstand

Zugprüfmaschine

Tiefung

Ritzhärte

FT-IR

The department “Coatings and Analytics” is responsible for all questions concerning corrosion protection by metallic coatings and non-metallic inorganic coatings. The main focus is on zinc-coatings, which are applied during hot-dip metal coating (batch galvanizing). Other research and industrial projects focus on strip galvanizing, spray metallization and electroplated coatings. We always keep close contact to our partners in research, industry and technology.

Further important fields are water distribution systems (drinking water installations and inhibited industrial water cycles) as well as corrosion, protection and repair of concrete and reinforced concrete.

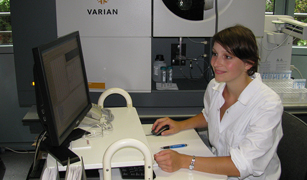

The department also includes a DAkkS-accredited analysis laboratory, which is perfectly equipped for all corrosion protection issues. This high-performance laboratory serves as the basis for all departments of the IKS for the clarification of cases of damage, for process monitoring and for research purposes.

Research and working focus:

- Hot-dip galvanizing (batch galvanizing, strip galvanizing), duplex systems

- Electroplated coatings

- Spray metallization / thermal spraying

- Water distribution systems (drinking water installations and inhibited industrial water cycles)

- Corrosion, protection and repair of concrete and reinforced concrete

- Corrosion analysis

- Analytical testing of VCI packaging material

Head of Department:

Dipl.-Chemiker Dr. Jürgen Triebert

Tel.: 0351 / 871-7118

Mobil: 0172 / 192 23 22

Fax: 0351 / 871-7150

E-Mail: juergen.triebert@iks-dresden.de

Geräteausstattung

Metallische und nichtmetallische Werkstoffe,

Feststoffe, Oberflächen

Rasterelektronenmikroskop mit EDX-Spektroskopie (REM/EDX)

Metallografie

Funkenspektrometer

Oberflächenkohlenstoff-Analysator

Infrarotspektrometrie (FT-IR, ATR und Mikroskop)

Gaschromatografie/Massenspektrometrie (GC-MS)

Wasserstoff in Metallen

Kontaktwinkel-Messgerät

Metall- und Anionen in Wasser und Eluaten/Aufschlüssen von Feststoffen

Atomemission (ICP-OES)

Atomabsorption (AAS Graphitofen)

Ionenchromatografie (IC)

The department “Corrosion protection and process engineering” is concerned with issues of corrosion protection in different industries with technological orientation. Technical solutions for the corrosion protection are treated from an engineer’s point of view and are accomplished, both, profoundly and application oriented. This broad and practical perspective is achieved by the cooperation of scientists, engineers and technicians. The traditional work scopes of practical corrosion protection are important, but also new fields of work are explored.

The department “Corrosion protection and process engineering” works in the following sectors: Surface pre-treatment and surface preparation procedures prior to joining and coating, electrocoating, corrosion protection in the joining technology, corrosion protection of material combinations and different special applications.

The latest achievements from completed and on-going research and industry projects regarding the current state of the art serve, in connection with the broad spectrum of analytical possibilities, also as a basis for qualified evaluation of cases of damage and quality-assuring supervision on construction sites as well as consulting services.

Research and working focus:

- Surface pre-treatment and preparation prior to application of metallic and organic coatings and adhesives

- Development of wet chemical surface pre-treatment systems and procedures

- Development of new mechanical pre-treatment procedures

- Abrasive testing

- Electrocoating

- Development of corrosion protection concepts when using different materials

- Corrosion protection after separating and joining operations

- Changes after loading in the interfaces metal/coating or metal/adhesive

- Combined mechanical and medial loads

- Assessing the corrosion protection in the steel and vehicle construction

- Evaluation of cases of damage

Head of Department:

Dr.-Ing. Jörg Gehrke

Tel.: 0351 / 871-7110

Mobil: 0172 / 192 2325

Fax: 0351 / 871-7150

E-Mail:joerg.gehrke@iks-dresden.de

Geräteausstattung

Vorbehandlung und Applikation

Kleingalvanikanlage

Pulverbeschichten

Prüfung

Schwingprüfmaschine mit Kondenswasserkammer

Dynamische Differenzkalorimetrie

Thermogravimetrische Analyse

Versuchsaufbau zur Prüfung von Beschichtung zur

Verträglichkeit mit kathodischem Korrosionsschutz

Zugprüfung mit Temperierung